Read All About It: Is Technology Taking the Challenge Out of Competitive Bowling?

Super Bowl by Pearl Tesler

ReadWorks

Have you shot a 300?”

Among serious bowlers, that’s the question. Scoring a 300 in bowling is the ultimate dream-12 strikes in a row, the perfect game. It’s like pitching a no-hitter in baseball.

Michael and Darren Tang, brothers 13 and 16 years old from San Francisco can each answer yes to the 300 question. Michael bowled his first perfect game when he was just 10 years old.

Not long ago, the idea of a 10-year- old bowling a 300 game would have been laughable. A perfect bowling game used to be rare; in 1970, nonprofessional bowlers in the United States bowled 854 perfect games. Today, scores of 300 are much more common, last year, nonprofessionals bowled more than 52,000 perfect games. What accounts for that staggering increase? Technology.

Invisible Tech

Step into your local bowling alley, and you might think you’ve been transported back to the 1950s. The air smells of hot dogs. There’s a jukebox in the corner. And there are those same silly shoes your parents and grandparents wore when they bowled.

Don’t be fooled, though. Bowling is as high-tech a sport as any other. And the technological changes have been significant. They’re easy to miss, though, because they’re pretty much invisible. Super Bowl Few non-bowlers know that a thin layer of mineral oil is applied to the first two-thirds of a bowling lane. Oil reduces friction, the resistance of objects to sliding. The oil is applied mainly to protect the lanes from damage. But it also has a huge impact on the game because it affects the motion of the ball.

In the 1970s, oil was sprayed on the lanes haphazardly, usually by hand. That made bowling more difficult. The balls moved erratically, skidding and veering unpredictably. Today, $40,000 machines apply oil to lanes in precise patterns. The perfection of machine-oiled lanes helps bowlers control the path of their balls, leading to more strikes, says Paul Ridenour, a research engineer at the United States Bowling Congress (USBC). He tests all the factors that can affect a bowling game and uses his findings to set the official standards for bowling equipment.

The Hook

Bowling balls have come a long way too. The “house balls” you use at the bowling alley are made with the same simple, solid plastic used in the 1970s. But competitive bowlers such as the Tang brothers prefer modern, multilayered balls made from a additive-enhanced plastics with holes custom-drilled to suit hand size and bowling technique. If you could peel back the layers of a modern bowling ball, at the center you’d find a dense inner core. With weird shapes and names to match-names such as Nucleus and Orbiter-the cores are designed to alter the balls’ moment of inertia. Moment of inertia is a measure of how weight is distributed in an object.

The distribution of weight in a modern bowling ball can give it “trick” properties, causing it to change speed and direction partway down the lane. In particular, the core can help a bowler perfect the single most important shot in bowling: the hook.

Bowlers know that their best chance at knocking over all the pins is to hit the “pocket,” the space between the head pin and either of the two pins beside and behind it. Ideally, the ball should not hit the pocket straight on, but from the side, at an angle. How can you get a bowling ball to arrive at the pocket at an angle? Hook it.

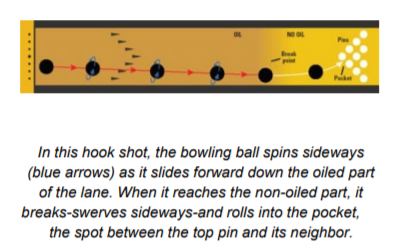

A bowler rolls a hook shot by giving it a strong sideways spin on launch. For the first half of the trip down the lane, the ball mainly skids on the oiled lane. But once it leaves the oiled part of the lane, the ball “breaks.” It encounters friction and begins to travel sideways, veering toward the pocket.

A ball with a dense inner core can hook even more strongly. As it rolls down the lane, it gradually changes its orientation, putting a fresh section of ball in contact with the oily floor. That produces more friction when the ball reaches the dry part of the lane, allowing for a stronger hook. An ordinary ball collects oil on a single unchanging ring around its surface, which means less friction and less hook.

Pore Reducer

Ridenour and his team made a surprising discovery recently. “We found that the single biggest influence on hook wasn’t the core, but the cover stock, the material covering the outside of the ball,” he says.

The key factor to improving the hook turns out to be porosity, the roughness of a surface at the microscopic level. An extra-porous ball effectively has microscopic spikes on it, which help it gain the friction needed to hook even on an oily lane. “You really can’t feel the difference,” says Ridenour. “But you can see it when the ball hooks.”

The USBC recently imposed new limits on bowling ball porosity to maintain the challenge of the game. “Somebody’s always going to want to build a better mousetrap,” says Ridenour. “Our job is to make sure that those mousetraps don’t give bowlers an unfair advantage.”