Steaming with STEM: Build Your Own Recycling Machine

You will build your own recycling sorting machines that use various methods, like magnets or puffs of air, to separate shreds of paper from paper clips. This is inspired by the real-world engineering challenge of separating various materials, like paper, plastic, and metals, that get combined in single stream recycling programs.

Materials

- Paper clips

- Paper

- Magnets

- Scissors

- Cardboard

- Tape

- Cups

- Optional: other construction/craft materials such as wooden craft sticks, glue, pipe cleaners, etc.

Science Behind the STEM

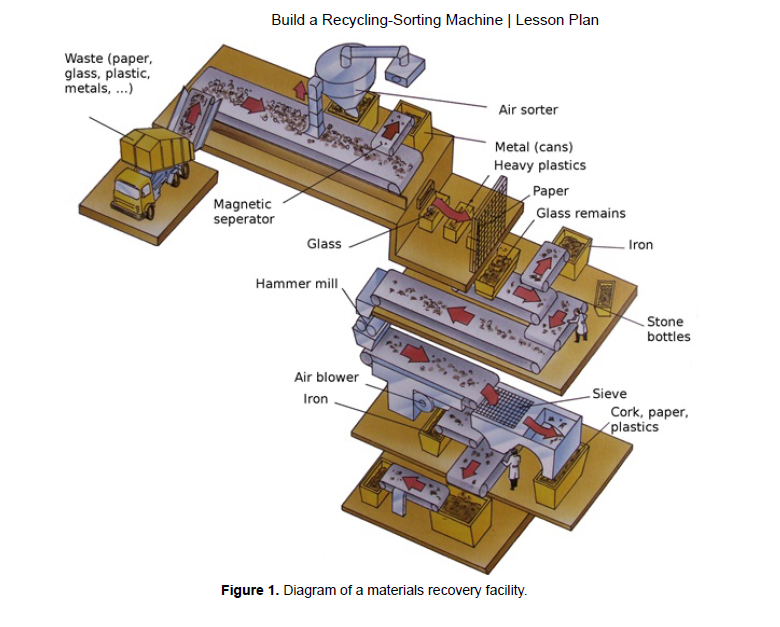

Single-stream recycling programs allow us to mix all our recyclables—like paper, plastics, and metals—in a single container. These containers are collected by trucks and transported to Materials Recovery Facilities. Look at diagram below. These facilities use a variety of machinery, combined with some manual sorting by humans, to separate all the different materials. For example, large magnets can pull ferrous metals, like tin cans, away from the rest of the waste. Puffs of air can blow lighter materials upward while heavier materials fall. Sieves allow small objects to fall through the holes while larger objects keep going.

Use this link to see how a sorting machine works.

The Big Sort: An Insider’s Tour of a Recycling Plant https://www.youtube.com/watch?v=nUrBBBs7yzQ&feature=youtu.be

Think About It!

- How difficult is it to sort the paper clips and paper shreds by hand?

- What happens if you blow gently on a pile of paper clips and paper shreds? What happens if you blow harder?

- What happens if you slowly bring a magnet towards the pile? Do the magnets need to touch the paper clips to attract them, or can they do it from a distance? Is there a certain distance you must reach before paper clips are attracted to the magnet? How many paper clips can a single magnet pick up?

- Can you think of any other ways to separate the two materials? If so, try them!

Directions

- Start with a well-mixed cup of 50 paper clips and 50 paper shreds.

a. The cup mixture must be poured into the sorting machine. The machine should sort the paper clips and paper shreds into two separate containers (e.g. cups or boxes).

b. The machine and its parts can be operated by hand, and you can blow into the machine to create puffs of air. However, no manual sorting (individually plucking out paper clips or shreds) is allowed.

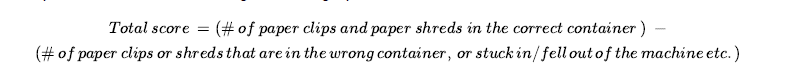

c. The machine’s performance will be scored using the following equation.

- You can draw your idea for a sorting machine.

- Build a prototype of your sorting machine. You may want to test individual parts of it as you build to make sure the parts are working as intended.

- Make a data table to record the performances of your design across multiple tests. The format of the table will depend on the criteria you decided on.

For example, you could record the number of correctly/incorrectly sorted paper clips/shreds, or the total time required to complete sorting. After each test, fix your machine.

- After completing construction and testing, you should perform a final test. Compare results across from the prior tests.

Reflection:

Why did your machine or method work or not work?